Request A Quote

Product Description

Find out more designs!

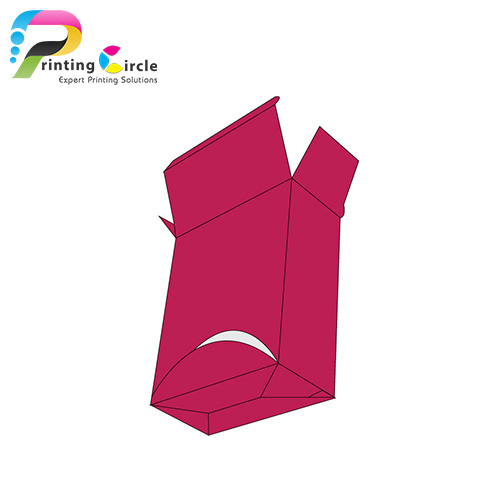

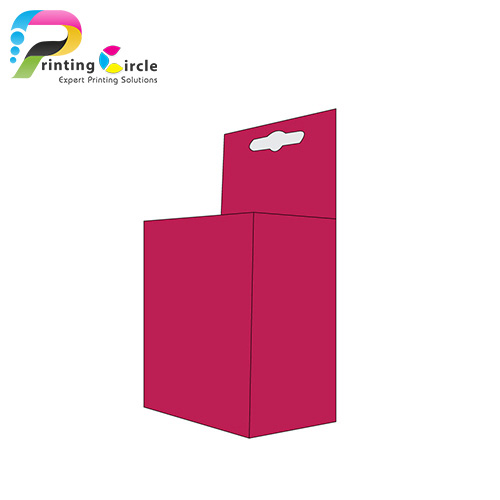

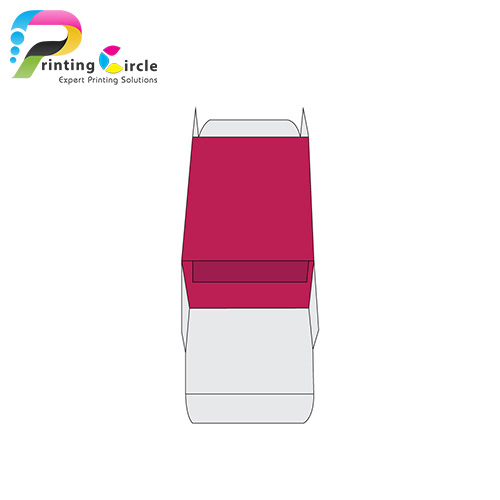

Simplex trays can be designed according to the need. The shape and size of these trays can be set accordingly. If you plan on keeping objects that are a little bit bigger than usual, then we can provide you custom simplex trays that are also bigger than usual. The coating of the packaging materials can be done using gloss varnish or lamination, matte varnish or matte lamination and spot UV. These are the techniques that we have. It requires creativity and expertise to handle these standard tools in a manner that every time there is a new look that comes to the fore. The coloring of the boxes is also a fascinating part of our procedure. If you already have the colors set for your business, then we just have to look at what labeling options go best with that color and the nature of the product. If the colors are yet to be decided, then our free design support will help you come up with the best possible options. The labeling on the box and the fonts are also discussed. The way your labels go on the surface of your box is a vital side that needs to be covered with complete regard. Our experts can guide you better about things such as text visibility and how it can be improved. The designers that we have in our team can provide tremendous insights regarding the current trends and the latest fads. There are no set formulas in art, and there has to be a novelty factor in each of the designs that we put out on the market, so the task to differentiate the designs and at the same time make them appealing is an art that our designers have mastered through years and years of practice.

An overview of our printing

We jump to printing immediately after the design has been approved. This is not the final approval that we are talking about. There are, and physical sampling can also be given to customers. If they feel the need to see a few sample models before the whole order has been printed, we can arrange that. The printing starts after successful physical sampling and mockups.

During the printing stage, we do not use any such materials or chemicals either as substrates, additives or cleaning detergents that are harmful to our own health and our environment. We make sure to keep it eco-friendly and green. We use materials that are recyclable and sustainable. Our quest to find more cost-effective methodologies will continue in the future as well as we are committed to the cause of keeping our planet green and healthy.

The printing techniques that we have with us are offset, digital and screen printing. Each of these three techniques has different attributes. They all enable printing, but all three have their own sets of pros and cons. We use them accordingly as per the requirements.

Satisfaction Guaranteed

Printing Circle provides complete satisfaction to the customers through top-notch work and impeccable customer service. We offer free shipping to our clients. The turnaround time is quoted as 12 to 15 working days.

Over the years we have developed quite a reputation in the packaging industry. We have been able to sail past through our competitors by putting our focus on three aspects of the business — quality, Creativity, and Conduct. Our quality is the best in the market. Creativity has been used in the design and Research and development departments. And our conduct refers to the way we carry ourselves with the clients. Due to this thinking, we have built a client base that is dedicated and loyal.

Product Specification

| Dimensions | All Custom Sizes & Shapes |

| Printing | CMYK, PMS, No Printing |

| Paper Stock | 10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock |

| Quantities | 100 - 500,000 |

| Coating | Gloss, Matte,Spot UV |

| Default Process | Die Cutting, Gluing, Scoring, Perforation |

| Options | Custom Window Cut Out, Gold/Silver Foiling, Embossing, Raised Ink, PVC Sheet. |

| Proof | Flat View, 3D Mock-up, Physical Sampling (On request). |

| Turn Around Time | 4-6 Business Days , Rush |

Customer Reviews

Related Products